A complete guide to shipping by pallet

Here's what you'll find on this page

Pallet shipping defined

Shipping by pallet refers to the transportation of goods from one location to another using multiple boxes or parcels stacked on pallets. Pallet shipping is a cost effective solution, allowing you to pay in bulk rather than shipping each box individually.

How much does shipping a pallet cost?

The price of shipping by pallet is determined based on a number of considerations, including the weight and size of the pallet, the origin/destination of the shipment, and the shipping method. Our online quoting tool can provide you with a free pallet shipping quote today.

Weight

The weight of the pallet is the most important factor in determining the shipping cost. Having an accurate weight up front will help keep your shipping costs in budget.

Size

Pallets that are larger or have irregular dimensions tend to cost more to ship.

Distance

Pallets shipped long distances will cost more to ship than those shipped short distances.

Shipping method

Pallets shipped via less than truckload (LTL), could cost less to ship than pallets shipped via full truckload (FTL).

Save on pallet shipments with these cost savings tips

- 1. Plan ahead

Know the size and weight of your palletized shipment to acquire the best rate. - 2. Compare carriers

Use our free online quoting tool to get a quick quote comparison from multiple carriers. - 3. Ship during off-peak times

Ship on weekdays or avoid holidays to potentially result in lower transportation costs. - 4. Standardize shipments

Get a uniform price for pallet shipments, regardless of the goods being shipped. - 5. Review freight classifications

Verify your products are classified correctly to help avoid adjustments.

Five advantages of shipping by pallet

Pallet shipments are a popular and economical choice when shipping freight. Here are five reasons why:

- 1. Protection: Pallet shipments offer a sturdy base for stacking goods—preventing goods from shifting during transit.

- 2. Movability: With the use of a forklift or pallet jack, pallet shipments are easy to move—saving on labor costs.

- 3. Sustainable: Because they can be reused multiple times, pallets save resources—and shipping costs.

- 4. Standardized: Standard sizes and dimensions make it easier for carriers to handle and transport pallet shipments.

- 5. Economical: Since pallets are relatively inexpensive to purchase or rent, they are a cost-effective way to ship freight.

Standard pallet dimensions and sizes

The Consumer Brand Association (CBA—formerly known as the GMA) influences the consumer packaged goods industry around the globe.

Their standard pallet dimensions are 48"X40"—roughly 4'x3.33' or 160 sq. feet if you're looking for a quick conversion. Despite the group's name change in 2019, pallets of this size are still commonly referred to as GMA pallets.

| Standard pallet sizes |

| 48" x 40" |

| 42" x 42" |

| 48" x 48" |

More than 30% of pallets produced in the U.S. each year are GMA pallets. The next most common pallet dimensions are 42” x 42” and 48” x 48” respectively.

Choosing the right shipping pallet

There are several types of pallets, with names based on their construction. Below are the five most common pallets seen in shipping and a brief description of what separates them from one another.

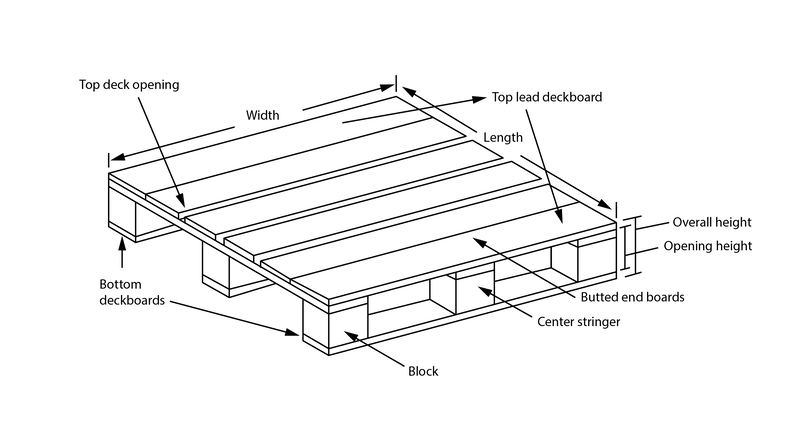

1. Stringer pallets

Stringer pallets are built with 2"X4" wood, plastic, or metal stringers. These pallets use boards known as "stringers" that run between the top and bottom deck boards to add increased load support.

These pallets can come in either a "two-way" or "four-way" design. Two-way pallets allow for forklifts to enter from two sides and are sometimes referred to as "unnotched." Four-way pallets allow forklifts to enter the pallet from any side.

2. Block Pallets

Block pallets are typically sturdier, made with both parallel and perpendicular stringers. They are a four-way pallet that uses cylindrical posts to stabilize the top deck. These pallets can vary significantly. There are a variety of configurations that exist for block pallets. Models are available with or without top or bottom boards.

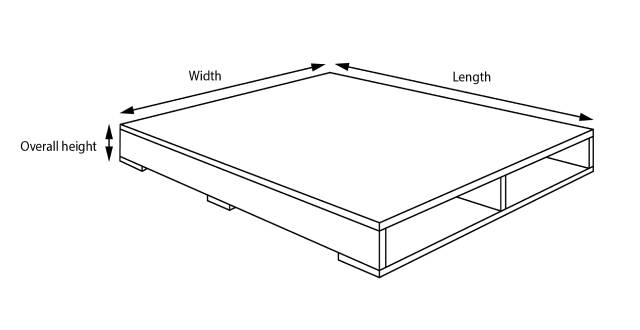

3. Solid Deck Pallet

The Solid Deck pallet offers a superior alternative to traditional pallets, particularly when it comes to handling heavier or uneven loads. Unlike standard pallet sizes with gaps between deck boards, the Solid Deck boasts a fully connected top surface, creating a seamless platform for optimal load stability. This unique design acts as a built-in preventative system, effectively distributing weight and minimizing the risk of shifting or toppling during transport or storage.

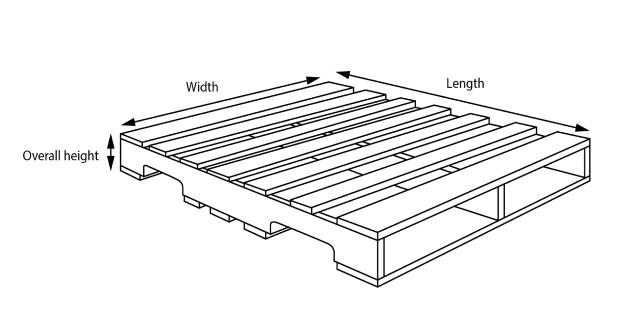

4. Double Face Pallet

As the name implies, double face pallets have decks on both the top and bottom of the pallet. The addition of a bottom deck strengthens the pallet and more evenly distributes the weight of the load.

These pallets come in both reversible and non-reversible models. Reversible models can hold a load on either side. To tell the difference between a reversible and non-reversible pallet, check the density of the board placement on each side. Non-reversible pallets should have one side that is sturdier than the other.

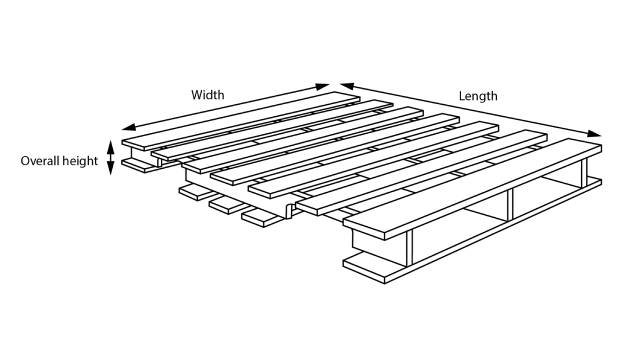

5. Double Wing Pallet

When looking at the pallet directly, double wing pallets have the appearance of "wings" because top and bottom deck boards extend beyond the stringers.

In addition to these common types, there are also specialized pallets designed for specific applications. Choosing the optimal pallet for a specific application depends on various factors such as load weight, load size, product type, and transportation needs.

Planning a freight pallet shipment?

Discover unbeatable freight rates with Freightquote’s easy-to-use online tool.

Whether your pallet shipments are set to go or you’re still deciding on the pallet sizes and type—we've got you covered.

When it comes to shipping a pallet, Freightquote provides competitive shipping rates and support for your shipment needs.

Book a shipment

How to ship freight pallets

Packaging and preparation is considered the most important piece of shipping by pallet. When preparing your goods on a pallet, it’s important to secure your freight to the pallet and assess it to make sure your item(s) are properly balanced and securely in place.

The two recommended methods for securing items to a pallet are strapping and shrink wrapping. Regardless of your selected pallet shipping method, inspect your shipment before pickup and make sure your items are firmly in place and have not shifted.

1. Strapping pallets

When strapping items to a pallet, use at least two straps and loop them through the forks of the pallet. Also firmly tighten or ratchet the straps in place for the most secure fit.

2. Shrink wrapping pallets

Depending on the shipment, make at least five full wraps around the entire shipment and pallet with shrink wrap, ensuring that the finished shipment and pallet feels like one solid piece.

3. Consider fragile items for pallet shipments

Beyond firmly securing your shipment to a pallet, fragile goods can also benefit from a simple device called crush cones. These tell the carrier not to stack other items on top of your freight. They are small, often triangular, cones that can be attached to the top of your shipment by straps or packing tape.

Check out these how-to videos of our pallet shipping experts strapping, stacking, shrink wrapping pallet shipments

Blocking and bracing of pallets

When prepping items on a pallet, ensure they are properly balanced and secured in place.

Learn how

Crating pallets and stacking

Carriers often prefer palletized loads to help maximize space inside the trailer, making the shipping process more convenient for both parties.

Watch how

Banding and stretch wrapping pallets

See what it takes to properly secure your items on a pallet with bands or shrink wrap.

See howOther considerations for shipping pallets

The following pallet shipping best practices can help minimize the risk of damage while in transit. Consult with a Freightquote shipping expert for help meeting your shipping needs.

- Choose the right sized pallet: Choose a pallet of suitable size and strength to support the weight of your items. Consider using pallets with additional support beams or reinforcements for added stability.

- Find the right carrier: Select a reputable carrier with experience and a strong reputation. Leverage LTL carrier reviews in our online booking tool to inquire about expertise and past service levels.

- Distribute the load evenly: Distribute the weight evenly across the pallet, placing heavier fragile items at the bottom and lighter items on top. This helps maintain balance and stability during handling and transit.

- Set clear expectations Knowing what to expect during the shipping process is a smart way to make sure your freight moves efficiently.

- Track shipments throughout: Obtain a tracking number from the carrier to monitor the progress of your shipment. When you book with Freightquote, our online shipment tracking tool does all the work for you!

Understand the ins and outs of pallet shipping

By staying informed about industry trends you can streamline operations, minimize costs, and deliver goods with confidence. Book your next pallet shipment with confidence using our free online booking tool.

Get free quotesFreight pallet shipping FAQs

What is a standard pallet size?

The standard pallet size is 48"x40" with each deck board being 3 1/2" wide by 5/16" thick. Other pallet sizes may differ across industries, but the pallet described above, based on GMA standards, is the most common and makes up more than 30% of all pallets used in the United States.

How tall is a standard pallet?

The standard pallet is 6 1/2" tall before it is stacked with boxes.

How much does a standard pallet weigh?

Pallet weight may vary, but in general standard pallets weigh 30–48 lbs.

How much weight can a standard pallet hold?

A standard pallet can hold up to 4,600 lbs.

How much does shipping a pallet cost?

The cost of shipping pallets depends on a variety of factors such as material, size, product type, and location. Use our online quoting tool to get free quotes for pallet shipments today.

How does pallet shipping can help businesses improve efficiency?

- Improve the accuracy of shipments

- Reduce the amount of damage during shipping

- Reduce the amount of time it takes to load and unload freight

- Increase the amount of freight that can be shipped in a single load